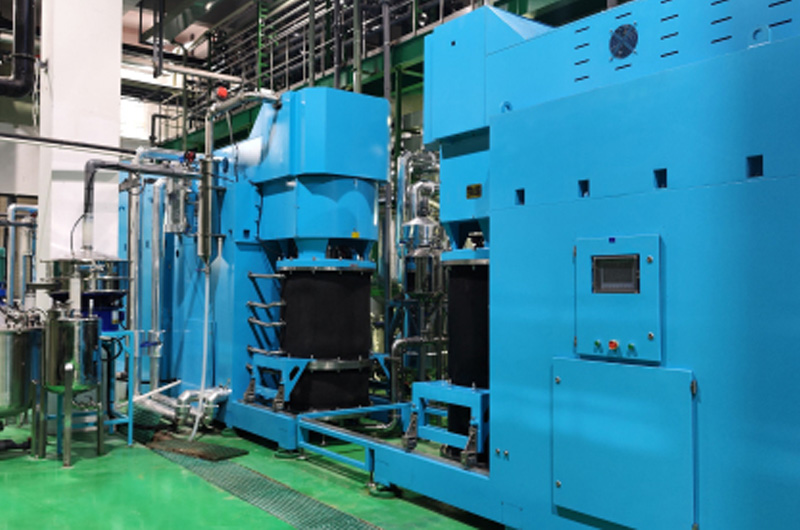

Modern high-end cosmetics, such as foundations, sunscreens, serums, lipsticks, and mascaras, strive for the ultimate skin feel: silky, smooth, non-greasy, and non-cakey. This is achieved through the meticulous processing of pigments, sunscreens, and active ingredients using advanced nano sand mills like the dual-power nano sand mill.

Core Applications:

Ultrafine Homogenization of Pigments and Colorants: Cosmetic-grade pigments such as titanium dioxide (TiO2) and iron oxide must be ground to a size significantly smaller than skin wrinkles (typically <10μm) to achieve natural coverage and a smooth application, avoiding a powdery feel or white residue. The vertical nano sand mill delivers exceptional results in this critical step.

Critical Processing in Sunscreen Products: Nano-sized titanium dioxide and zinc oxide, the core ingredients of physical sunscreens, must be processed to nanometer sizes using sand mills to eliminate their inherent "whitening" effect, achieving transparent, invisible UV protection while maintaining effective sun protection. A pre-mixing dispersion tank ensures perfect feed uniformity before entering the mill.

Encapsulation and dispersion of active ingredients: Many vitamins (such as vitamin C) and whitening ingredients are difficult to stabilize. Sand mills, including pin disc mill and ceramic milling machine designs, can efficiently disperse them in emulsions or liposomes, improving their bioavailability and stability, ensuring product efficacy.

Technical Requirements:

Technical Requirements:

A cosmetic-grade sand mill must primarily comply with GMP (Good Manufacturing Practice) standards. It must be constructed of 316L stainless steel or higher, with a mirror-polished surface, ensuring no blind spots and easy cleaning and sterilization. The equipment must operate smoothly, be quiet, and precisely control temperature rise to protect heat-sensitive ingredients. Options such as the laboratory sand mill are ideal for R&D and formula validation, while high-shear models like the pin mill grinder and dd mill provide additional flexibility for special formulations. Sanitary mechanical seals ensure absolute cleanliness and safety during the production process—standards that extend beyond cosmetics into fields like carbon nanotube slurry and battery slurry coating.