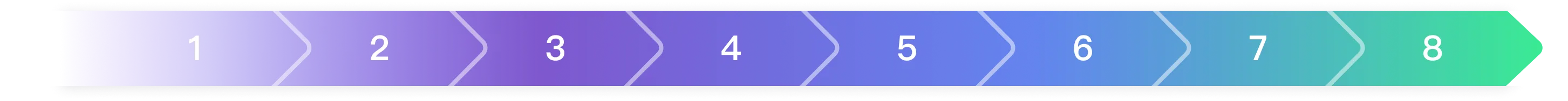

1. Consultation and docking: Professional technical docking personnel to provide high-quality service docking

2. Process design/layout design: Professional technical personnel carry out process design, and senior engineers with 10 years of experience conduct site surveys and conduct overall layout design.

3. Free experiment:The laboratory is fully equipped to eliminate your pre-purchase concerns with accurate data

4. Sign the contract and arrange production:After the two parties sign the contract, the company arranges to release the order tasks for scheduling.

5. Equipment production: The project manager coordinates production and holds weekly production meetings to track production progress and ensure on-time delivery of quality.

6. Installation and debugging/personnel/accompanying personnel training: On-site installation and debugging and one-on-one professional training for operators to make them familiar with the working principle and program operation of the equipment.

7. Operational acceptance: According to the pre-established acceptance standards and procedures, conduct a comprehensive inspection and evaluation of the performance, function, stability and other aspects of the equipment after transportation for a period of time, and complete the acceptance.

8. After-sales service: Free warranty within 12 months due to non-human reasons; the equipment exceeds the warranty period.

Accompanying R&D

During the customer's R&D stage, Yifu's expert consultants and technical team provide a full range of technical support and are equipped with professional equipment to work with customers to solve various challenges encountered during the R&D process. Through this close cooperation, we help customers successfully complete research and development tasks and ensure the successful advancement of projects.

Data Verification

Yifu Company is equipped with small test lines, pilot lines and advanced laboratories to provide customers with comprehensive product data verification testing before achieving large-scale mass production. This process ensures that products maintain excellent quality and performance during mass production, thereby meeting customers' high standards.

High quality mass production

During the product production process, we first use professional equipment to conduct comprehensive quality inspections on the raw materials. The processing stage is handled by professional equipment and senior technical personnel to ensure fine processing. Assembly is performed by experienced technicians, ensuring precise assembly of components. Before shipment, we conduct water testing, pressure testing and other tests to ensure the quality and reliability of the product.

Project Delivery

Before raw materials are put into storage, professional equipment is used to conduct comprehensive quality inspections; in the processing stage, senior technical personnel operate professional machining equipment; in the assembly stage, experienced technical personnel are responsible; before shipment, water testing and Pressure test and other tests to ensure product quality.

On-site debugging, accompanying childbirth

After the equipment is installed, the equipment will be debugged on site to meet the technical specification requirements of Party A's owner. After debugging, personnel will be arranged to accompany the production so that problems can be solved at any time during the production process without affecting Party A's production progress and quality.

Equipment usage training

Yifu has written complete equipment usage training materials, and provides professional technicians to conduct one-on-one equipment usage training for operators, so that operators can become familiar with equipment operating principles, program operations, daily maintenance, Emergency operations, etc.

After-sales, maintenance, consultation

Yifu provides 24-hour online after-sales service, responds quickly within 2 hours, and arranges personnel to provide after-sales service; Free warranty for non-human reasons within 12 months; outside the warranty period, we will continue to provide users with high-quality technical maintenance Serve.

Confidentiality work

Keep client confidential information strictly confidential, including technical solutions, technical data, technical results, technical information, operating methods, experimental results and other technical information and commercial information, and take measures to protect confidential information, such as limiting access , sign a confidentiality agreement, and encrypt files for storage and transmission.

fruitful, that is the harvest of autumn! In full swing, it is the scene of a billionaire busy! Since the beginning of autumn, Hubei Yifu has been working hard to catch up on production and work hard to catch up on orders. It has been a busy scene, and the scene is busy and orderly.

Hubei Yifu, the industry-leading new energy material testing line, has been officially put into operation after continuous assembly and debugging. It is fully equipped with various material performance tests and can test lithium iron phosphate, lithium iron manganese phosphate, sodium materials, silicon Carbon, conductive agents and other new energy materials!

New energy material testing line, including grinding system, spray drying, kiln, airflow crushing and other lithium iron phosphate material testing line equipment. The testing line equipment adopts the current domestic mainstream advanced equipment, and is equipped with various experimental instruments and The equipment is suitable for small and pilot tests, and can meet the experimental scale of products from tens of kilograms to hundreds of tons.

Panoramic view of test line

Panoramic view of test lineThe grinding section uses our two 30L horizontal sand mills, equipped with three 500L mixing tanks and one 1500L finished product tank. It is also equipped with filters, iron removers, chillers, diaphragm pumps, etc., and at the same time, according to the material According to the grinding needs, it can be matched with different types of sand mills such as vertical sand mills to easily achieve fine grinding of materials.

Spray drying uses the GL-5 spray dryer produced by a well-known domestic manufacturer. The evaporation capacity is more than 50 kilograms per hour. The atomization method uses high-speed centrifugal atomization.

The kiln adopts this 16-meter-long two-layer, two-row roller kiln produced by Suzhou Yunqigu. It adopts an atmosphere furnace structure and a furnace body sealing design. The common temperature is 600-850°C, and the daily production capacity is 1.1 tons.

Air flow grinding, the QLF-200 air flow grinder produced by Suzhou Jinyuan Sheng has the characteristics of no temperature rise, no pollution, little wear and low energy consumption. The production capacity is 50 kilograms per hour.

At the same time, we use ultrasonic vibrating screen (Navigat), dry powder electromagnetic iron remover (Zhongyu), ultrafine powder degassing spiral packaging machine (Guangzhou Henger) and other domestic leading production line equipment. The equipment in each link is seamlessly connected. After careful debugging, the overall test line operates stably and the effect is remarkable!

Panoramic view of test line

Panoramic view of test lineThe putting into use of Yifu New Energy Materials Testing Line provides great convenience for material testing, solves the current problems of insufficient equipment of manufacturers, long construction period, insufficient technical reserves, and immature production line control, and provides new opportunities for the industry. Provide comprehensive material experiment and testing support!

In addition to complete equipment and facilities, we are also supported by a top technical team in the new energy materials industry. We also have a large amount of production line application experience and data, which can provide comprehensive technical support for material characteristics, proportions, testing issues, test results, etc. Analysis to ensure qualified products are tested!

The full operation of this test line is a reflection of Yifu's courage to be the first, innovation and change, and also Yifu's determination and philosophy to devote to the development of the new energy industry. In the future, we will continue to serve the industry with our own strength, empower material grinding production, and contribute to the output of high-quality materials!