Recently, Southern Finance Omnimedia Group launched the 2024 fifth season of the "High-Growth Enterprise Forum·In-depth Research and Omnimedia Reporting of Gazelle Enterprises in the Guangdong-Hong Kong-Macao Greater Bay Area" project, further innovating omnimedia coverage, professional research, database construction, branded operations and resource transformation, and creating brand projects and media integration innovation projects that are deeply rooted in the Bay Area.

Cheng Hao, a renowned reporter from Southern Finance, visited Infor's Dongguan office to interview Ms. Yang Xiaoyan. The two sides conducted an analysis of the company's operations, innovative R&D mechanisms, market environment, and policy services.

Q1

A: Yang Xiaoyan: The company was founded in 1999. Initially, it was relatively small. Through our persistence, we have continuously expanded our comprehensive delivery capabilities and achieved significant success. We have been developing for 25 or 26 years. Our professionalism and focus have earned us our current position in the industry and recognition throughout the industry.

Our revenue has grown from 100 million to 300 million, and then to 500 million to 1 billion. The same is true for our technological innovation. In the past three years, we have made many technological breakthroughs that have led the development of the industry. This has also brought many changes to the entire supply chain, including optimizing products to improve performance, reducing production line costs and increasing efficiency.

Q2

A: Yang Xiaoyan: Our innovation capabilities are primarily reflected in our technological innovation, the strength of our technical team, and our innovative strategic collaborations with customers. Because our company has a high pursuit of technology, we will continue to pursue this path of technological innovation.

R&D personnel account for approximately 10% of our company's staff. Their primary focus is optimizing existing products and developing new materials grinding technologies. From the exterior to the structure, we conduct comprehensive R&D, followed by optimization and iteration. Based on customer needs and market changes, we listen closely to industry trends and develop cutting-edge technologies to enhance the quality of our end-user products.

Q3

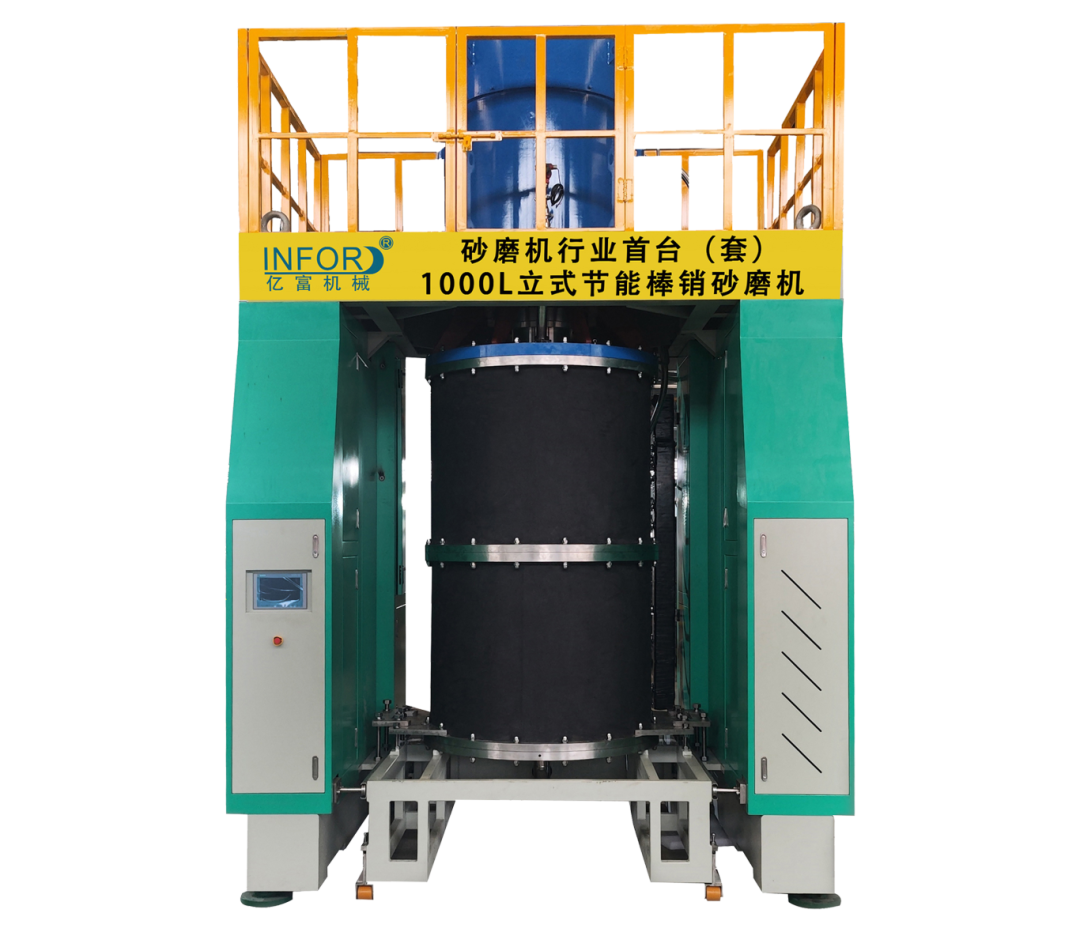

A: Yang Xiaoyan: First, it's reflected in the comprehensive competitiveness of our products. For example, our vertical sand mills, with their ultra-fine grinding, zero clogging, high efficiency, and low energy consumption, have received widespread acclaim from customers. I'm proud to say that our Infor brand is well-known among vertical sand mill buyers worldwide.

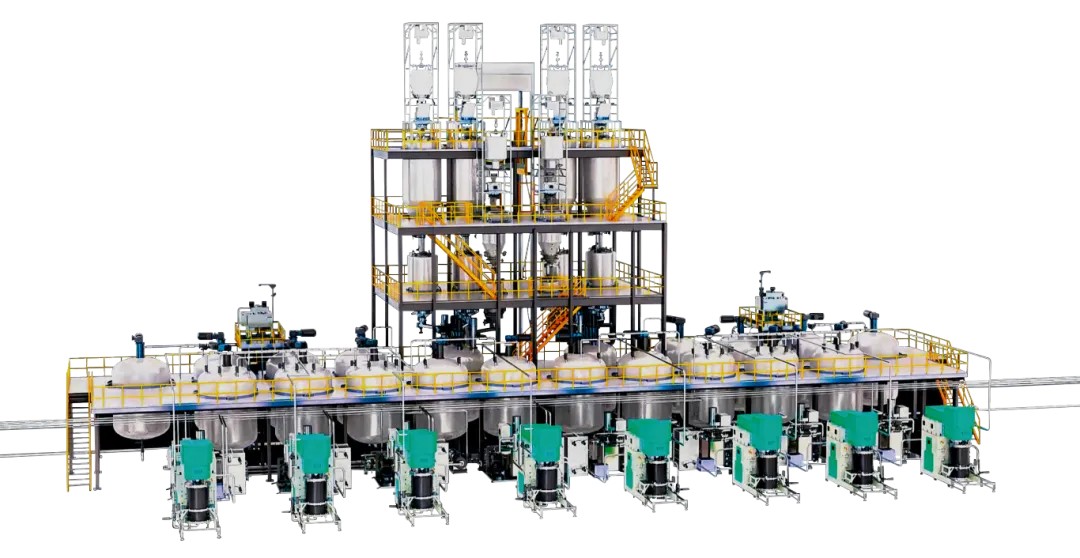

Secondly, we have strong delivery capabilities. Currently, our two production bases in Dongguan and Hubei have reached a monthly production capacity of over 200 sand mills. In terms of installation, we have extensive experience in installing and commissioning large-scale production lines, which will speed up installation and delivery.

Third, we offer comprehensive services. For example, we have a comprehensive testing facility for customers to conduct comprehensive pre-production testing. We have a large team of experts available to provide technical consulting services, and numerous offices and agents nationwide ensure rapid response and service.

Q4

A: Yang Xiaoyan: We are in awe of and admire imported equipment from countries like Germany, Switzerland, Japan, and South Korea. They started earlier, have a longer history of development, and have a deeper understanding of technology, resulting in higher precision equipment.

Compared to these countries, domestic equipment offers the following advantages: first, faster innovation and performance that better meets the needs of domestic companies. Second, we have a cost advantage: imported equipment is typically two to three times more expensive than domestic equipment. Third, in terms of timeliness and service quality, we are more efficient and have a more advanced service philosophy.

In recent years, the proportion of imported equipment in China has been decreasing. In the future, new energy equipment may be fully domestically produced. Of course, imported products still have certain performance advantages in certain components, and this is also an area where our domestic components need improvement.

Q5

A: Yang Xiaoyan: I think overseas expansion is already underway, and we are actively preparing for it. We are currently in a good time to practice. Regarding large-scale expansion, I anticipate it will be next year. We will play a synergistic and supporting role in the industry. Leading companies like CATL and BYD will gradually establish more factories around the world. That will be the time for us to expand globally, as we are always following their lead.

We currently have our own sales company in North Africa. Whether we'll build a factory in the future will depend on market development. We have agents in Japan and South Korea, an office in Indonesia, and are currently focusing on establishing offices in Europe and the United States.

Q6

A: Yang Xiaoyan: In the future, our technological innovation will continue to focus on intelligence and energy conservation. I've been working on energy conservation for four years, and we will continue to help our clients optimize their processes. Energy consumption is a significant factor affecting their production costs.

Currently, projects are growing larger, and larger equipment is a trend. We are also actively developing and reserving large-capacity equipment with a capacity of 1,000 liters or more. Regarding intelligent technology, we are gradually applying artificial intelligence to our sanding production lines, making both individual machines and production lines more intelligent and smarter, thereby comprehensively improving production efficiency and optimizing production costs.

Our new industrial park is nearing completion, and we will soon be moving into production and offices. In addition to expanding our site, we will continue to invest in talent and technology research and development to build a strong foundation for providing the industry with superior sanding production lines.