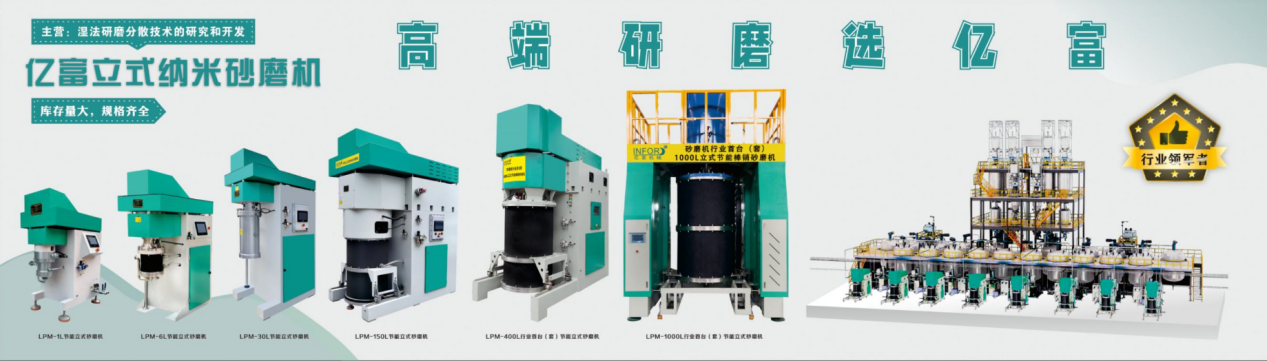

As an important part of the production of new energy materials, sand mills are directly related to production efficiency, equipment life and production safety. The following is a detailed summary of the key points of switching on and off the production of new material sand mill equipment, aiming to help you clearly understand and implement it effectively.

(1) Safety inspection

1) Personal protection: Ensure that operators wear personal protective equipment such as protective clothing, hard hats, protective glasses, masks, and earplugs.

2) Equipment inspection: Check whether all parts of the sand mill are intact, whether the fasteners are loose, whether the lubrication system is sufficient, whether the cooling system is smooth, and whether the electrical circuit and control system are normal.

3) Environmental inspection: Confirm that there is no debris piled up in the working area, that the ventilation is good, and that the emergency stop button is eye-catching and easy to reach.

(2) Material preparation Check whether the specifications, quality and ratio of lithium iron phosphate raw materials and grinding media (such as glass beads, ceramic beads) meet the requirements. Ensure that the raw material inlet and outlet are unobstructed and there is no risk of blockage.

(3) Parameter setting According to the production process requirements, reasonably set the sand mill's speed, grinding time, temperature control and other parameters. Verify whether the display data of the control system is consistent with the actual set value to ensure accurate control.

(1) Sequential start-up First start the cooling system to ensure that the equipment is running at a suitable temperature. Then start the lubrication system to provide necessary lubrication for key components. Finally, start the main motor and gradually adjust it to the set speed to avoid instantaneous high-load startup.

(2) Monitor the operation. Pay close attention to the operating status of the sand mill, including vibration, noise, temperature and other indicators. If any abnormality is found, stop it immediately for inspection. Regularly check the grinding effect through the observation window or sampling port, adjust the grinding parameters in time or shut down the machine for cleaning.

(1) Gradual deceleration. When completing production tasks or needing to shut down for maintenance, the speed of the sand mill should be gradually reduced to the minimum to avoid the impact of sudden shutdown on the equipment.

(2) After cleaning and maintenance, clean up the remaining materials and grinding media inside the equipment in a timely manner to prevent caking or corrosion of the equipment. Check and clean the inlet, outlet and filter to ensure smooth flow.

(3) Shut down the system. After shutting down the main motor, shut down the lubrication system and cooling system in sequence to ensure that the equipment stops running completely. Cut off the power supply, unplug the power plug, and lock the equipment control cabinet door to ensure safety.

(1) Regular maintenance: According to the requirements of the equipment maintenance manual, perform regular maintenance on the sand mill and replace worn parts to maintain stable equipment performance.

(2) Training operation: Ensure that operators have received professional training and are familiar with equipment performance and operating procedures to avoid misoperation.

(3) Emergency plan: Develop an emergency plan for sand mill failures and emergencies, and organize regular drills to improve response capabilities. To sum up, the switch-on operation of lithium iron phosphate sand mill equipment involves multiple links, and each step needs to be meticulous to ensure smooth production and the safety of personnel and equipment. By strictly implementing the operating points, not only can production efficiency be improved, but the service life of the equipment can also be effectively extended and maintenance costs can be reduced.