In the field of industrial fine grinding and dispersion, zirconia beads serve as the core grinding medium. Owing to their exceptional physicochemical properties, they have become a key material for achieving high-efficiency material refinement in industries such as lithium battery manufacturing, coatings, and ceramics. Among them, yttria-stabilized zirconia beads (YSZ beads) stand out for their superior performance, dominating high-end grinding applications.

From the perspective of composition and performance, the core value of zirconia beads is determined jointly by their material composition and manufacturing process. As the "golden partner" of sand mills, YSZ beads typically contain 95% zirconium oxide and 5% yttrium oxide as a stabilizer. This composition endows them with both ultra-high hardness and excellent toughness—yielding a Mohs hardness of 7–8.5. Consequently, they can efficiently break down material particles under high-speed collisions while minimizing self-wear and preventing impurity contamination, which is crucial in the fine grinding of lithium battery materials with stringent purity and fineness requirements.

The manufacturing processes of zirconia beads vary. Common zirconia powder synthesis methods include the hydrothermal and co-precipitation processes, while bead forming techniques typically involve rolling or dropping methods. Different manufacturing routes affect the beads' physicochemical properties and overall quality, thereby influencing their performance in lithium material grinding. In sand mill applications, the key performance indicators for zirconia beads include wear resistance, hardness, sphericity, and consistency.

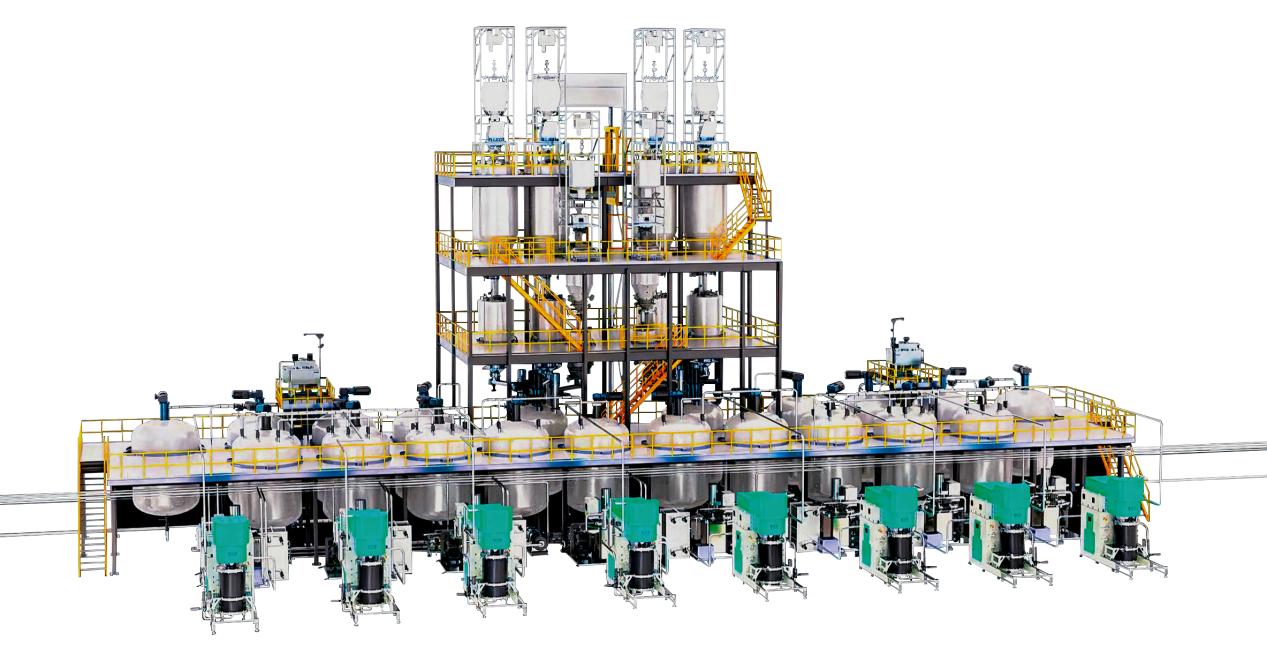

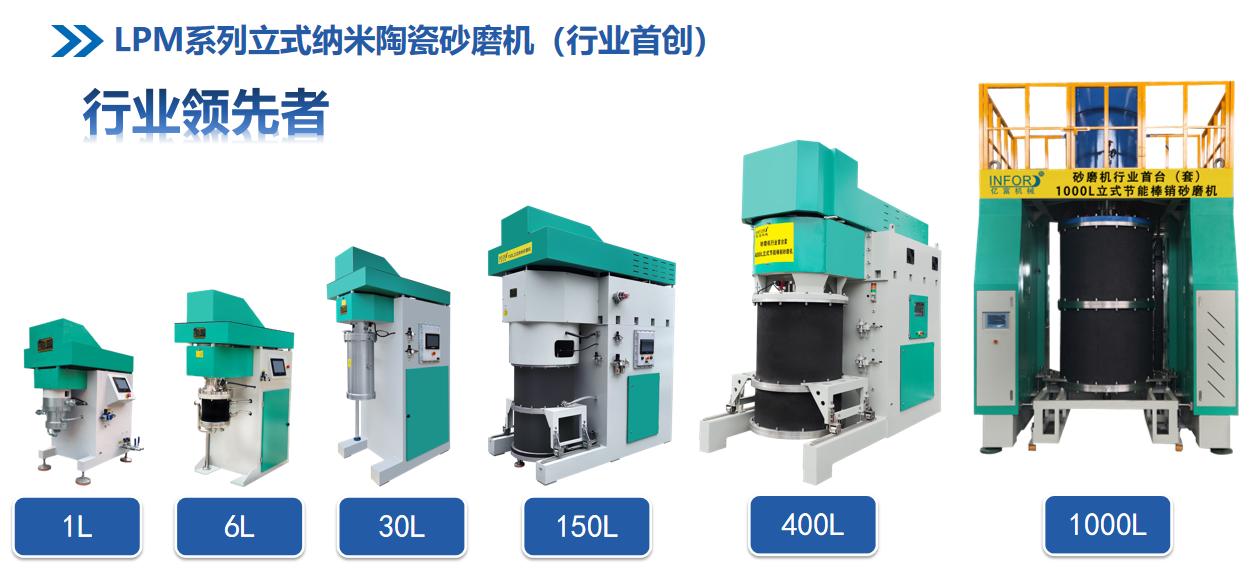

In practical sand mill operation, the selection, filling ratio, and parameter matching of zirconia beads collectively determine the overall grinding efficiency. Bead selection follows the principle of "particle size matching": conventional horizontal sand mills commonly use zirconia beads in the 0.1 mm–2.0 mm range, while high-end equipment such as the Infor Machinery vertical sand mill can accommodate ultra-fine beads as small as 0.03 mm. Typically, the bead diameter should be approximately 1,000 times the target particle size—for example, to grind a material to 0.1 μm, 0.1 mm zirconia beads are recommended to balance grinding efficiency and fineness.

The filling ratio of zirconia beads in a sand mill generally ranges from 70% to 85% of the chamber volume, and can be estimated using the formula:

Theoretical Filling Volume = Effective Grinding Chamber Volume × Filling Ratio × Bulk Density of Beads, where the bulk density of YSZ beads is typically 3.6–3.7 g/cm³. Insufficient filling reduces grinding efficiency, while excessive filling increases equipment load and bead wear.

More importantly, the sand mill and zirconia beads form a synergistic system. The hardness and wear properties of the beads determine the grinding limits of the sand mill, while mill parameters such as rotational speed, flow rate, and pressure must be adjusted accordingly. For instance, when using high-hardness YSZ beads, the rotational speed can be increased to enhance grinding efficiency; conversely, when using lower-hardness beads, the speed should be reduced to minimize wear. Regular maintenance of the sand mill—such as cleaning the grinding chamber and inspecting the dispersing disk for wear—also extends the service life of the beads and prevents uneven stress or increased breakage due to mechanical faults.

Zirconia beads are not merely consumables, but integral components deeply coupled with the sand mill system. In industrial production, only through the scientific selection of bead type based on material characteristics, precise control of filling ratios, and optimization of equipment parameters can the full potential of the sand mill be realized—achieving efficient, stable, and low-wear fine grinding performance.