The particle size and particle size distribution of LFP materials have a crucial impact on material performance. LFP has a one-dimensional ion channel, so it is necessary to shorten the diffusion distance of lithium ions and improve the diffusion efficiency of lithium ions by reducing the particle size. If the positive electrode material has the morphology of spherical particles, it has advantages in fluidity, bulk density and compaction density. Therefore, the preparation of spherical particles will help improve the electrochemical performance of the material."

Lithium battery electrode materials have strict requirements on the content of metal foreign matter, and magnetic foreign matter such as iron and nickel are the most important metal foreign matter. They are usually removed by permanent magnets or electromagnetic iron removers. The main harm of metal foreign matter is to reduce battery safety. If the positive electrode material contains metal element, metal particles will dissolve during the charging process and deposit and grow into metal dendrites at the negative electrode, piercing the diaphragm causes internal short circuits, which will cause thermal runaway. In the preparation process of lithium iron phosphate products and their raw materials, magnetic metal element will inevitably be mixed with, mainly from equipment wear of stainless steel and other materials during the production process.

Therefore, non-metallic materials should be used as much as possible for components in LFP production lines: If gold-bending materials are inevitably used, spray-coated tungsten carbide or Teflon coatings (such as PTFE or ECTEE, etc.) should be used to protect them to reduce the chance of metal foreign matter mixing into the material. Permanent magnet iron deductors generally use rotating magnetic rods made of neodymium iron boron, while electromagnetic iron deductors use the magnetic effect of current to magnetize the grid screen. The magnetic field strengths of both are 7000-8000Gs. Although electromagnetic iron deductors can achieve higher magnetic field strength, because LFP materials themselves have a certain magnetic properties," too high magnetic field will cause the LFP itself to magnetize, which will make the iron deductor absorb impurities with the material, and it will not be possible to remove iron normally. Electromagnetic iron deductors have advantages in contact area and cleaning and adsorbing impurities, so the iron removal effect is relatively better.

In the poor conductivity of LFP materials itself, the electron conductivity and ionic conductivity can be effectively improved by uniformly coating carbon (C), making LFP have significant application value. At present, the main use of raw materials such as glucose and sucrose as carbon sources. After high temperature decomposition, C element is produced. Some of them participate in chemical reactions or are discharged in the form of tar, and the rest achieves uniform carbon coating on the surface of the positive electrode material.

In addition, polyethylene glycol (PEG), which is often one of the raw materials for production, can also provide a carbon source for achieving uniform carbon coating. In the process of large-scale preparation of LFP powders, if material transportation is involved between different processes, a diaphragm pump is generally used to transport slurry with pipelines, and the powder is transported between different processes by positive or negative pressure pneumatic conveying method. Positive pressure transportation is to use a silo pump to send the material together with high-pressure gas to the receiving silo; negative pressure transportation is to use a vacuum pump (such as a Roots pump) downstream of the process to extract gas, and use a vacuum cavity upstream, and the material will be transported to the next process.

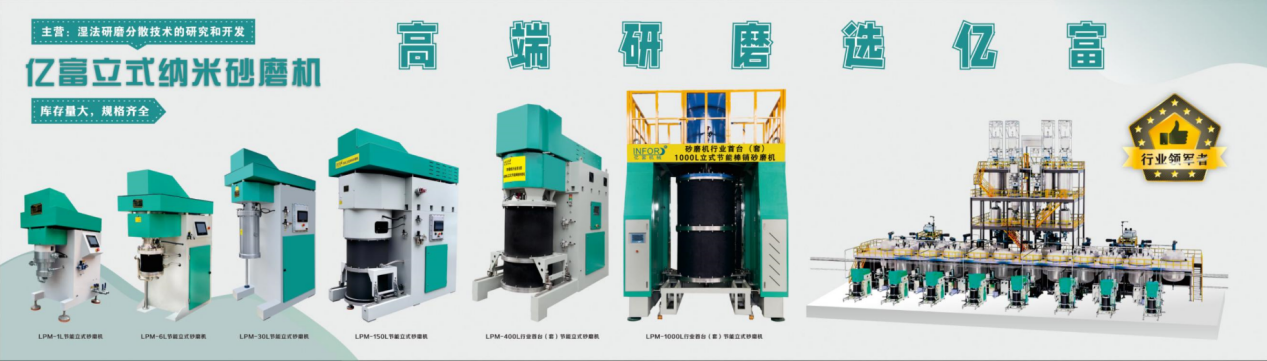

Infor Machinery was founded in 1999. For more than 20 years, it has provided customers with the concept of "respect for the industry and proficient in the industry and standing in the world with sincerity" to provide customers with comprehensive solutions for nanomaterial grinding single machine and system solutions for the current 13,000 square meters factory area of Guangdong headquarters, more than 40,000 square meters of production plant in Xiangyang, Hubei, and a 100 acre production base under construction, 100+ patents, 400+ professional teams, and 1,000+ cooperation cases.

Currently, the company's equipment has the characteristics of large-scale, intelligent, and energy-saving. It was the first in China to launch an energy-saving sand mill, the first to use large-scale vertical equipment, and the pioneer of direct drive sand mills. It has special sand mills such as turbines, rod pins, and plate pins. The capacity ranges from 1-1000L have the characteristics of stable operation, high efficiency, low energy consumption, large flow, ultra-fine, and pollution-free.

Infor is committed to exporting high-quality equipment to the new energy materials industry and making comprehensive breakthroughs in the fields of new materials such as lithium iron phosphate. There are hundreds of large-scale domestic and foreign cooperation cases, which fully empower the development of the new energy industry. Welcome friends in the industry to call for consultation!